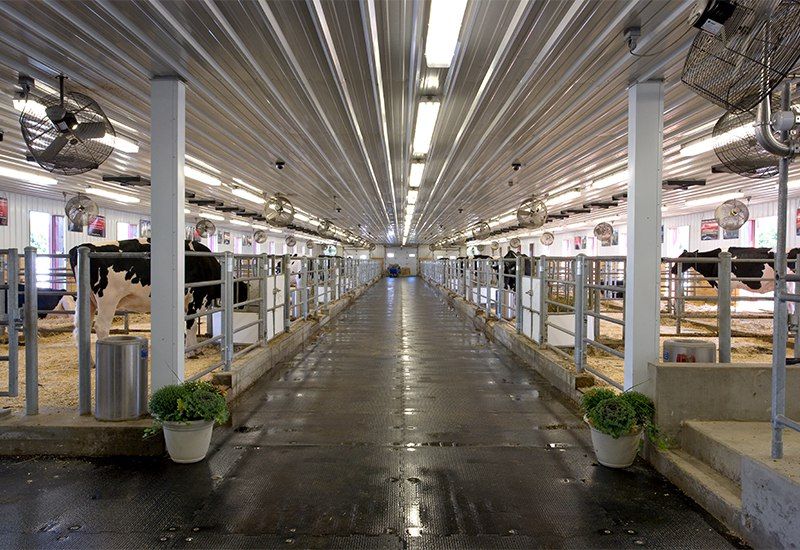

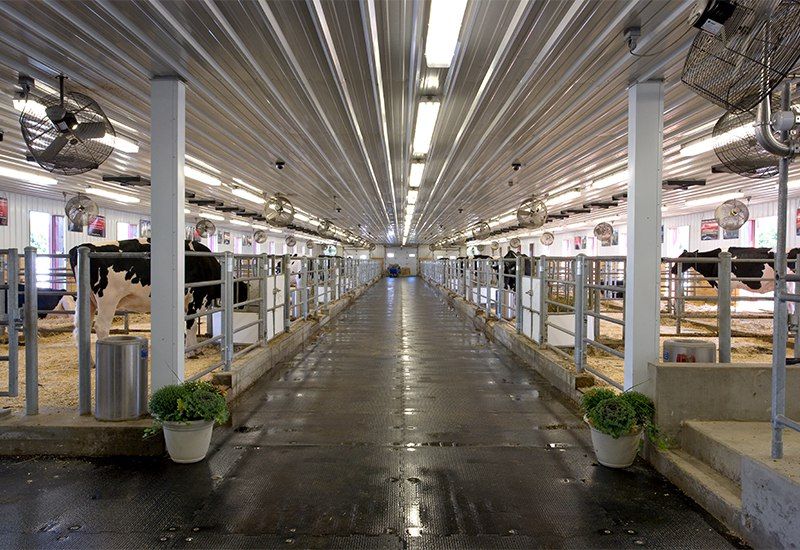

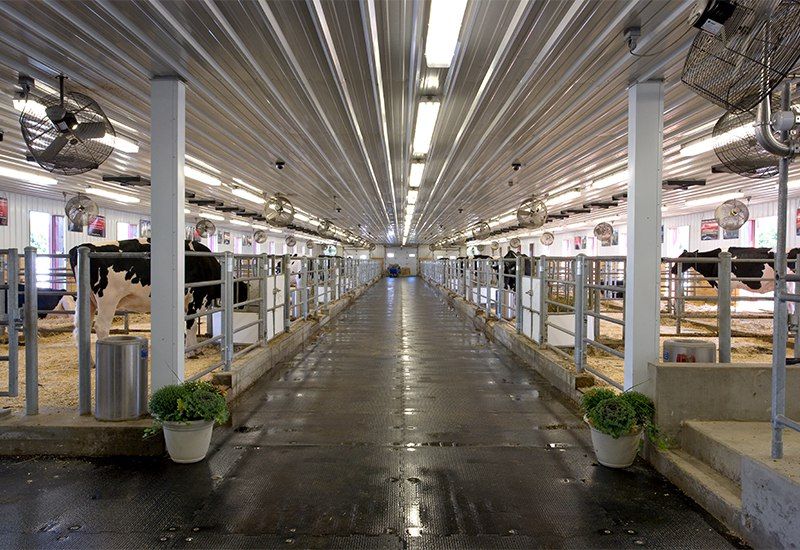

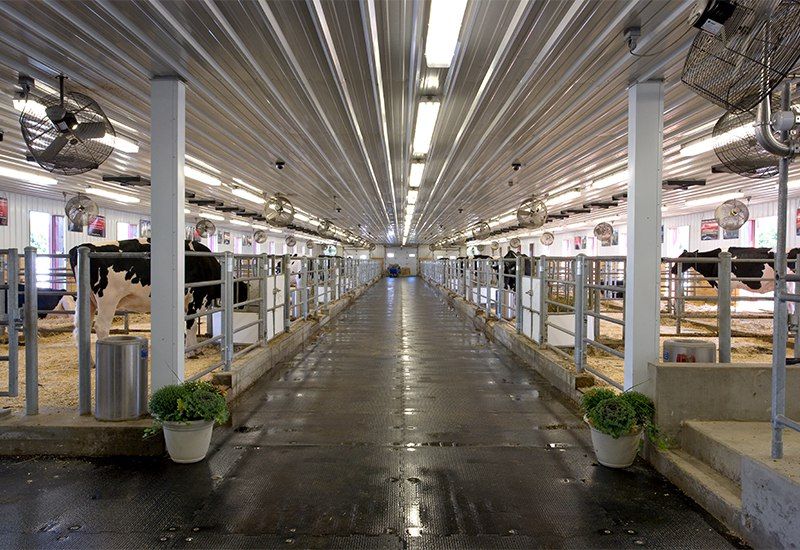

The key to a building that works is a team that understands. That means knowing that free stall barns, holding barns, parlors and dry cow facilities have different needs, requirements and ways to improve cow comfort and production. But it also means understanding your land and plans for future expansion, regulatory issues, and your dairy management style and flow.

Ventilation. Will your facility be naturally ventilated or mechanically ventilated? What about cross ventilation? How will the ventilation impact construction, operation and production?

Movement. To create a stress-free environment, your facility design must help you manage movement. Throughout the day, your facility needs to allow cows to comfortably go from a resting place to feed to water. For milk production, your facility should allow for a calm, worker-induced movement, with careful consideration paid to turning areas, traction and gating.

Feed Management: Feeding is a big part of dairy production cost, and one that your building can help you manage. But first comes understanding your current feeding operation and space constraints.

Materials: Part of engineering is speccing the right materials for the facility. For instance, will your concrete hold up to the salts in the feed? Will the steel used in your roof withstand the gas and moisture of a dairy environment?

Manure Management. Like any livestock facility, a dairy operation needs to meet regulations for manure management. But it doesn’t stop there. With multiple cleanings a day, a dairy produces a lot of waste water. How will you get rid of that water and is it compliant? What about sand recovery? Summit reduces your risk by designing facilities that increase operational efficiencies for manure management, turn waste streams into valuable nutrients, and allow for a greater level of environmental stewardship.

Future Expansion. When you look five, ten, even twenty years down the road, do you see expansion? If so, should the building be designed for that growth? Will you able to leverage your existing facility without constricting yourself?

Land: How does your existing acreage impact your operation today and expansion tomorrow? Does your plan need to include additional acreage? What if you can’t get more land? If that’s the case, how can your buildings help you maximize your acres?

Structural Engineering: A dairy barn, by nature, is a large open space; the sort that can catch a lot of wind, with a roof that can hold a lot of snow. It must be designed and engineered for wind and snow loads appropriate to the size of the building, its location and its region. Rest assured, Summit’s are.

Robotic Milking: Is your existing milking parlor tired and in need of replacement now or down the road? Are you considering a new facility with robotic milking? If so, Summit knows how to incorporate this innovative technology into the design so it functions with and for your operation.

We provide high quality, proven options so you can choose what’s best for your business and overall investment.